Brains

Digitalize Industrial Equipment Into Intelligent Assets

Empower your equipment with advanced AI for real-time condition monitoring, predictive maintenance, optimized performance, and streamlined decision-making.

Meet Brains,Your AI Co-Pilot That Thinks & Acts Like a Real Engineer

Just like a seasoned engineer at your side, Brains acts as an AI powered operations expert, enabling your equipment to Self-Monitor, Self-Diagnose, Self-Optimize & Self-Operate, unlocking autonomous and remote operations.

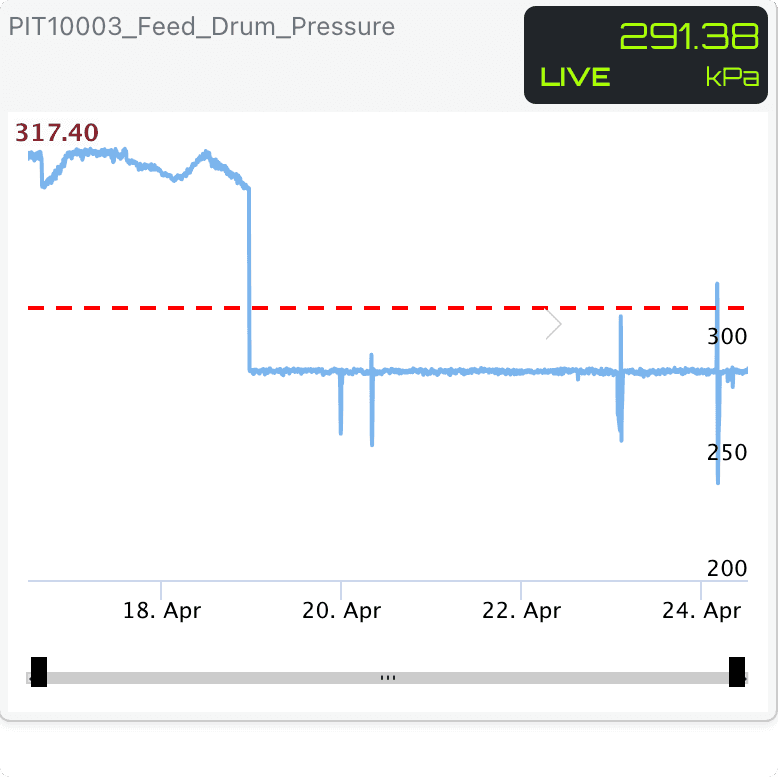

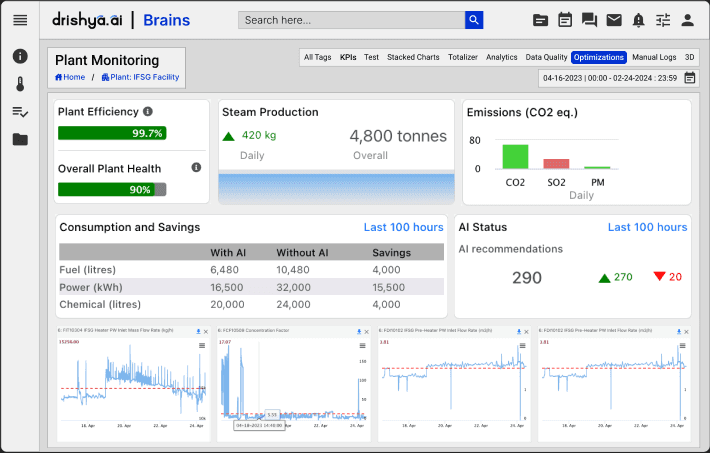

Realtime Plant Monitoring

Brains taps directly into the pulse of your plant. It seamlessly connects to your existing sensors and SCADA systems over IoT networks to collect real-time equipment data, providing a cost-effective and fast-to-deploy monitoring solution for operational visibility.

Collect, Store & Analyze Instrument Time-Series Data

Unlock insights from the past and present. Brains gathers high-frequency data from sensors, including temperature, pressure, flow, vibration, and more, creating a detailed operational history enabling trend analysis and benchmarking,

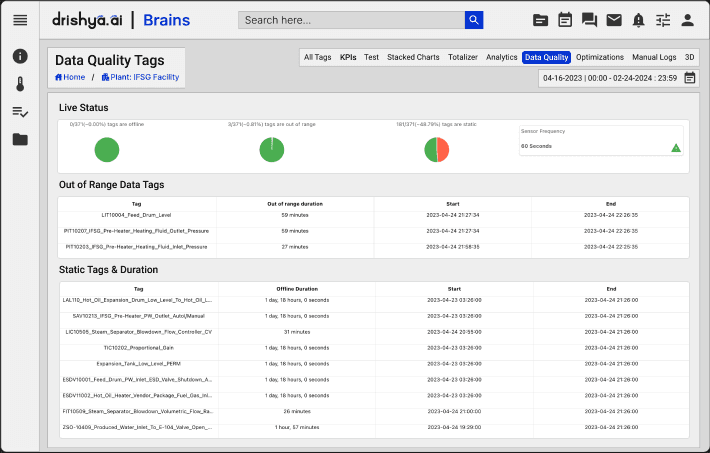

Identify Malfunctioning or Failing Instruments

Brains protects your operations from unreliable data. It proactively detects failing sensors or instruments, preventing you from making decisions based on faulty readings.

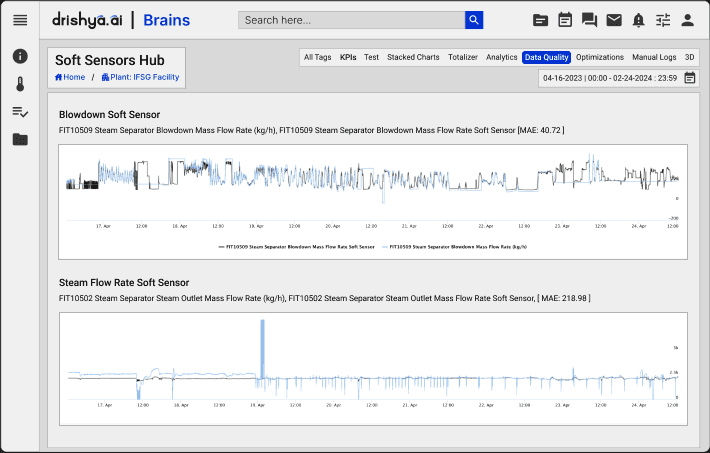

Measure What Can Not Be Measured With Soft Sensors

Get complete visibility into your processes. Brains combines readily available sensor data with AI models to estimate critical parameters that would otherwise require expensive or unavailable hardware.

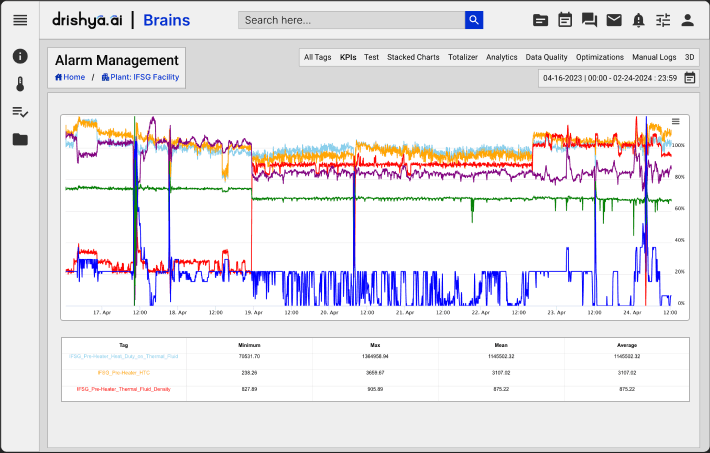

Smart Alarm Management to Focus on Alarms Which Matter & Avoid Noisy Alarms

Cut through the alarm noise. Brains declutters alarm dashboards, ensuring that operators only receive alerts that demand immediate attention and don’t get overwhelmed by a barrage of irrelevant signals.

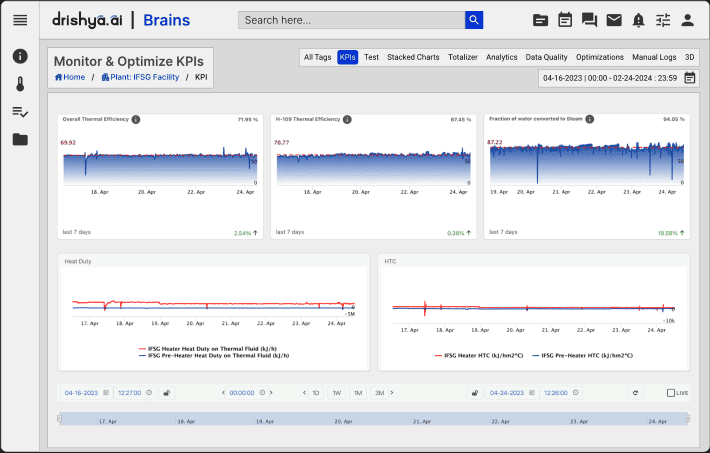

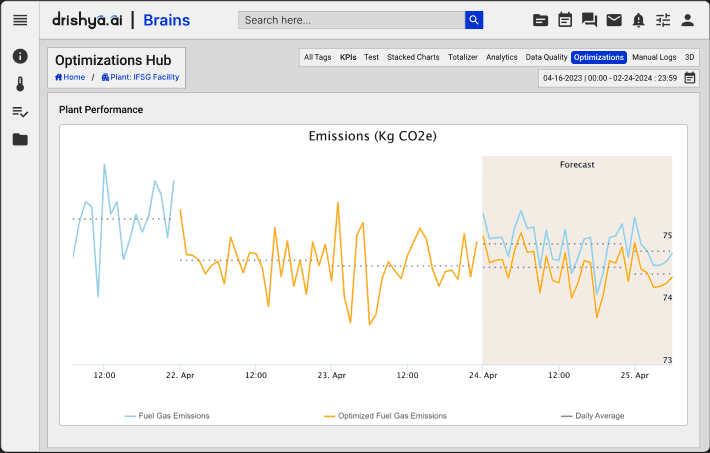

Analyze, Gain Insight & Optimize Equipment Operations

Get answers, not just data. Brains goes beyond visualizations, providing clear insights about equipment efficiency, performance bottlenecks, and opportunities for improvement.

Enable Autonomous & Remote Operations

Optimize operations from anywhere with Brains. Its remote monitoring and insights allow off-site engineers and experts to collaborate effectively, minimizing the need for on-site presence, and enabling autonomous fleet management.

With Generative AI,

Use Simple Prompts To Perform Advanced Engineering Functions

Brains pioneers generative AI built for the plant floor. Experience the power to analyze, troubleshoot, and optimize your operations using simple, natural language prompts.

Get answers to complex questions in seconds with simple prompts

Navigate Plant Operations From Real-Time Monitoring to Trend Forecasting

Extract Insights From Data For Decision Support

From Downtime to Uptime, Plant Performance Optimized

Eliminate operational waste, maximize output. Learn how Brains targets inefficiencies, reduces downtime, and drives significant gains in plant productivity through data-driven solutions.

USE CASE

Optimize Evaporator Operations By Predicting Fouling Resulting In Reduced Chemical Consumption

PROBLEM STATEMENT

Evaporator operations are hampered by an invisible threat: insidious fouling. Due to a lack of direct fouling measurement, chemical dosing is reactive and inefficient, leading to suboptimal performance, increased costs, and potential downtime.

SOLUTION

Brains brings clarity to the fouling problem by developing a real-time soft sensor to quantify fouling, transforming chemical dosing from reactive guesswork into an optimized, data-driven process.

OUTCOME

With Brains Soft Sensors, operators were able to monitor the rate of fouling, reduce chemical consumption by 8% and maximize yield

USE CASE

Blowdown Rate Optimization in Evaporators

PROBLEM STATEMENT

Blowdown control in evaporators is a delicate balance. Maintaining the optimal blowdown rate is crucial for efficiency, asset health, and cost control. However, unreliable blowdown flow measurement and manual control make it prone to errors, leading to over or under-blowdown situations.

SOLUTION

Brains deploys a multi-faceted solution to achieve blowdown optimization. It combines a data quality engine for real-time sensor glitch detection, a soft sensor for accurate blowdown flow prediction, an anomaly and state detection algorithm, and an HTC optimization algorithm for automated control.

OUTCOME

With Brains' solution, operators achieved optimal blowdown rates, reduced chemical usage, and minimized heat transfer losses. The plant realized estimated annual savings of $244,000 with a significant reduction in operating costs and a 2.5% improvement in overall evaporator efficiency.

USE CASE

Making Next Generation Equipment Intelligent & Scalable

PROBLEM STATEMENT

Modernizing equipment brings new operational hurdles. Next-generation equipment, while technologically advanced, often requires specialized expertise to operate and maintain, creating a bottleneck in scalable deployment and potential skill gaps.

SOLUTION

Brains empowers next-generation equipment with intelligence and connectivity. It adds an AI layer to these advanced assets, allowing real-time monitoring, remote optimization, embedded analytics, and fleet-wide management, bridging the operational knowledge gap.

OUTCOME

2X Increase in speed of commissioning with reduced requirement of specialized engineers at remote production sites.

Our Offices

Calgary, Canada

2017 Pegasus Road NE,

Calgary, Alberta,T2E 8C3

+1-877-374-7492 (DRISHYA)

Bengaluru, India

First Floor, 161, 4th Main Road, 7th Cross,

Chamarajpete, Bengaluru,

Karnataka, 560018

2025 Drishya AI Labs Inc. All Rights Reserved